Domů > Our products > Siliconized foils & papers (release liner)

Siliconized foils & papers (release liner)

Siliconized foils

Silicone foils (often also release liner/liner), are foils specially prepared for the application of silicone already in production.

Films according to requirements can have the following properties:

- antistatic,

- antimicrobial,

- biodegradable,

- made from recycled material,

- printed,

- with different release (break-off force)*

*siliconized foils are foils covered with a layer of silicone that changes their properties in the area of release or the possibility of tearing.

Foils can also be:

- puncture resistant,

- resistant to mechanical influences,

- resistant to temperature fluctuations,

- different types of water vapour, oxygen, fragrance, oil or UV light permeability.

Dimensions:

- Roll widths: min. 15 – max. 2200 mm

- Thicknesses: min. 10µ – max. 200µ

- Coils: min. 200 – max. 5000bm

Execution:

- single-sided

- double-sided

Types of silicone films:

HDPE (20 – 200µ)

High Density PolyEthylenen

The density of polyethylene is in the range of 0.93 to 0.97 g/cm3, it is temperature resistant in the range of -50 °C to 110 °C. High density polyethylene is also chemically resistant, odorless and suitable for direct food contact, non-toxic, recyclable. The film rustles, does not transmit water, minimally transmits water vapor and odors, exposed to the influence of UV radiation, it gradually disintegrates.

LDPE (20 – 200µ)

Low Density PolyEthylene

Films made from low-density polyethylene are clear, tasteless and odorless. Color can be ensured by adding colored pigments. Furthermore, with the help of additives, it is possible to adapt the properties of the film to the given requirements. LDPE film withstands the temperature range from -50 °C to +85 °C. LDPE films without added color concentrates are suitable for direct contact with food. For colored versions, it is necessary to observe a certain pigment concentration. From an environmental point of view, LDPE films are harmless and recyclable. They can be disposed of by incineration, during which no harmful substances are released into the environment.

PP (20 – 200µ)

PolyproPylen

PP film is specified by high toughness against breaking in bending. We usually deliver it in a clear version.

PET (10 – 125µ)

Polyethylene Terephthalate

From a certain higher temperature (200°C +), the foil is plastic – malleable – to liquid. After cooling, it becomes solid again. This process can be repeated for this film.

Siliconized papers

Siliconized papers (often also release liner/liner/silicone) are papers made specifically for applying silicone (coating).

It is often used as:

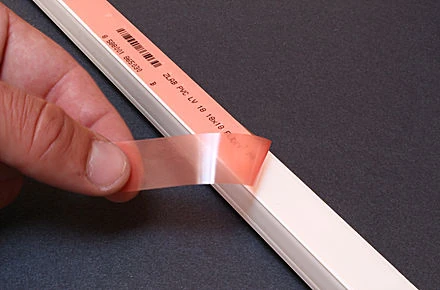

- non-stick coating protecting the glue on adhesive tapes, labels, stickers.

- support pad for self-adhesive films and other sandwiches intended for plotting or die-cutting.

- separation and anti-slip layer between adhesive surfaces, mixtures, bitumen?, rubber, etc.

- protection of presses and other technological equipment where there is a risk of overflows of glues, resins, plastics, etc.

- baking paper – separation non-stick mat used in baking

Dimensions:

- Baking paper: 41g/m2

- Glassines: 64 – 124g/sq.m

- Clay Coated Kraft (CCK): 42 – 137g/sq.m

- PE-Coated Kraft (PEK): 76-300g/sq.m

- Fluoropolymer coating for silicone adhesives: 80g/sqm

Execution:

- single-sided

- double-sided